Silica Monitoring

Silica Monitoring Melbourne and Victoria

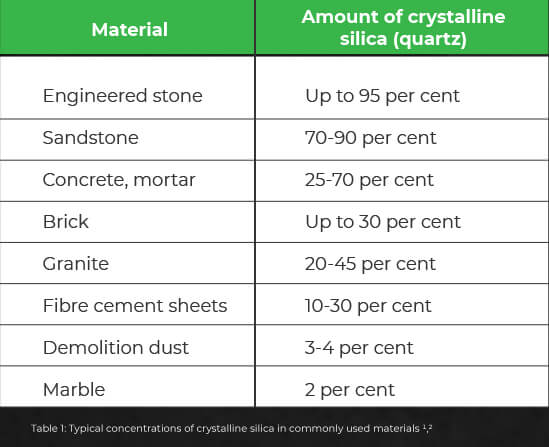

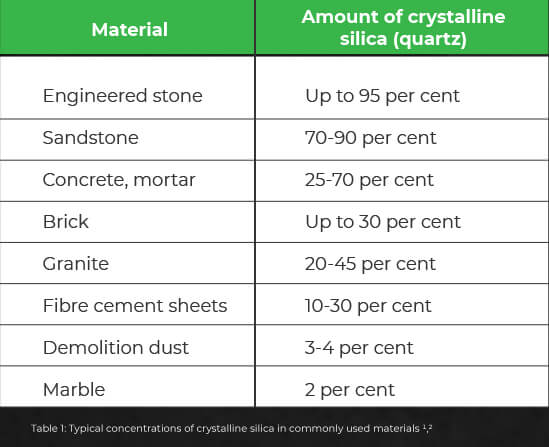

Crystalline Silica can be present in many building materials including sand, natural stone, engineered stone, concrete, mortar, gravel, brick, tiles and fibre cement sheeting.

Crystalline Silica dust is created when these materials are subject to processes such as drilling, grinding, cutting, sawing, and polishing.

Respirable Crystalline Silica (α-quartz) is the Crystalline Silica dust particles that become airborne very easily and are so small that they are not visible to the naked eye, making them easily inhaled and able to penetrate deep into the lungs.

This can lead to both short-term and long-term negative health impacts, including silicosis.

As of November 2021 a Compliance Code: Managing exposure to crystalline silica – engineered stone was published. If your work involves making, supplying or modifying engineered stone, there are legal obligations you need to comply with under the Occupational Health and Safety Act 2004 (OHS Act) and Occupational Health and Safety Regulations 2017 (OHS Regulations). This new compliance code gives you and your workplace practical instructions on how to comply with those duties and obligations.

By law employers must carry out air monitoring if they are not sure if their employees are exposed to levels of silica dust that are above the exposure standard or if they cannot work out if there is a risk to employee health without air monitoring.

WorkSafe Victoria recommends that employers take a precautionary approach and reduce employees’ exposure to below 0.02 mg/m3 (as an 8-hour TWA) to prevent silicosis and minimise the risk of lung cancer.

An ongoing air monitoring program is required to confirm that the exposure standard for respirable crystalline silica is not being exceeded. Employers need to conduct ongoing air monitoring at least once every six months.

Greenlight Environmental Services provides silica monitoring services for any workplace where there is a risk of exposure to Respirable Crystalline Silica dust.

Using calibrated, lightweight air monitors fitted to your workers, placed in their breathing zone, to measure their personal exposure, we can then provide a comprehensive report, comparing your results to the guideline levels and provide recommendations on how to manage and reduce respirable silica levels in your workplace.

Protect your workers today, call Greenlight today on 03 9048 4411 or enquire about a quote for silica air monitoring services now using the button below.

How Greenlight Can Help you Manage your Silica Dust Risk

If your workplace uses materials that may contain crystalline silica, or undertakes processes where silica dust is created, it is imperative that the exposure to respirable silica dust is monitored so the risk to your workers health is managed.

To ensure the exposure to silica dust in your workplace does not exceed the WHS Regulation Exposure standards, a thorough examination of your work site and the processes conducted by any workers is required.

At Greenlight Services, we offer silica testing and monitoring services, including:

- An inspection of the workplace

- Monitoring of exposure levels to workers through all processes where crystalline silica is used

- Air monitoring of the workplace

- Sample collection of materials

- Testing of collected samples in a NATA accredited laboratory

- Comprehensive reporting outlining any risks identified in your workplace

The illnesses caused by exposure to crystalline silica dust are all preventable, which means the effective management of the risk of exposure to all workers that can be achieved through comprehensive crystalline silica dust testing and monitoring services provided by our expert consultants is key to ensuring the long-term health of your workers. Don’t wait until it’s too late to ensure the safety of your team.

Call us on 03 9048 4411, email us at [email protected] or book our services online using the button below.

Employer and WorkSafe Requirements

It is a legal requirement of employers to ensure that their employees health is not being risked by exposure to crystalline silica.

To do this, an employer must conduct air monitoring in their workplace if:

- The employer is unsure as to whether their employees are exposed to silica levels that are higher than the exposure standard. The workplace exposure standard for respirable crystalline silica dust is 0.05mg/m3 as a time weighted average in an 8 hour period; or

- If the employer is unable to work out if there is a risk to employee health without the air monitoring.

Employers must also provide health monitoring of their employees if their health is likely to be affected by crystalline silica exposure.

It is highly recommended that employers take a precautionary approach to exposure to crystalline silica, by aiming to keep their exposure to below 0.02mg/m3 as an 8 hour time weighted average.

You can learn more about crystalline silica exposure and WorkSafe Victoria requirements here.

What is Silica and Respirable Crystalline Silica Dust?

Silica, also known as silicon dioxide, is a common and abundant mineral that is naturally occurring and makes us the major component of most rocks, stones, sands, and soils. A durable and stable element, silica exists in two forms – non-crystalline silica and crystalline silica. Non-crystalline silica does not cause the same kind of damage to our lungs as crystalline silica, thus is not considered a health risk.

Crystalline Silica

The hazardous form of silica is known as crystalline silica, with numerous types of Crystalline Silica existing. The most common of which, is Quartz, and due to its abundance and durability, the usage of Crystalline Silica is popular in many industries, particularly, but not limited to, building and construction. Crystalline Silica can be present in many building materials including sand, stone, concrete, mortar, gravel, brick, tiles, sandstone, fibre cement sheeting, and stone products that are either natural or engineered, such as stone bench tops.

When it is in its solid form and undisturbed Crystalline Silica is generally safe to handle and, in most instances, will not pose a risk to your health. It becomes hazardous to our health when silica dust is created through activities such as grinding, drilling, or sawing. This is known as respirable crystalline silica, where the dust particles are very small and can become airborne easily, which makes them easier to be inhaled.

What is silica dust and how is it created?

Silica dust can be created when materials that contain crystalline silica, such as concrete, sandstone, engineered stone products, and bricks, are subject to processes such as drilling, grinding, cutting, sawing, and polishing, among other activities.

The dust that is produced by these processes is known as respirable crystalline silica and it is this dust that poses a risk to your health.

Airborne silica dust is very fine and is usually not visible to the naked eye. Due to the small size of the respirable silica dust particles, they are not only easily inhaled, but they are also fine enough to penetrate deep into the lungs, which can lead to both short-term and long-term negative impacts on your health.

Why is Silica Dust Dangerous?

The fine nature of the silica dust particles makes them easily inhaled, where they can reach the deepest parts of the lungs (known as the alveolar tissue).

Repeated exposure to levels of silica dust greater than 0.05mg/m3 on an 8-hour Time Weighted Average may cause a number of short- and long-term health issues that mostly effect the respiratory system.

Exposure to silica dust can cause diseases such as emphysema, chronic bronchitis, lung cancer, scleroderma, kidney damage, rheumatoid arthritis, and silicosis.

What is Silicosis?

The biggest threat to the health of those workers who are exposed to silica dust particles is developing Silicosis.

Silicosis is an incurable lung disease where the tissue in the lungs becomes scarred from the exposure to respirable silica dust particles. The scarring occurs because when we breath dust in, our lungs try to remove it through coughing or bringing up phlegm, however, if we are unable to remove the dust, cells in our bodies attempt to remove them by engulfing with the aim to dissolve them.

However, the immune system cells are unable to dissolve silica dust particles, and it causes the cells to die which in turn, causes scarring of the lung tissue. Through repeated exposure, more scar tissue forms, and this can impact the ability of the lungs to absorb and inhale oxygen.

- Acute silicosis – Results from a large amount of exposure to silica over a short period (less than a year) and is rare.

- Accelerated Silicosis – Results from large amounts of exposure to silica over a short period that is greater than a year, less than 10 years. This is now becoming more common, particularly amongst stone benchtop workers.

- Chronic silicosis – results from low levels of silica exposure, over a period of more than 10 years.

Many of those who are in the early stages of silicosis are unaware as symptoms do not usually present until more damage to the lungs has occurred. As silicosis worsens, symptoms such as coughing, shortness of breath, loss of appetite, fatigue and occasional chest pain can occur.

There is no cure for silicosis, which is why air monitoring, and safety procedures are paramount to ensuring the long-term health of those at risk to exposure.

While there is no cure for silicosis, all silica related illnesses, including silicosis are preventable through the usage of correct procedures that reduce the exposure to and the production of silica dust.

Who is at Risk of Exposure to Silica Dust?

As crystalline silica is so abundant and durable, it has been used across many different industries. Some of the work industries and activities where silica dust may be present include:

- Stone Masonry – particularly significant for those who work with the creation and installation of stone countertops. This can be both natural and engineered stonework.

- Stone, Brick or Concrete cutting, particularly those who use a dry method.

- Mining and Quarry workers exposed to mineral ore treating processes.

- Excavation, tunnelling, and earth moving operations.

- Abrasive blasting.

- Foundry and Sand Casting.

- Labouring and Construction Activities.

- Paving and Surfacing work.

- Concrete or Masonry grinding, jack hammering and chiselling.

- Clay and stone processing machine operations.

Monitoring Silica Levels

Silica dust poses ones of the biggest risks to the health and safety of many workers in various industries across Australia.

The illnesses that are associated with exposure to crystalline silica dust are preventable if the correct safety measures are in place.

It is a Workplace Health & Safety regulation that the appropriate controls are put in place to manage the risks to the health and safety of any workers who may be using, handling, generating, or storing any hazardous materials or chemicals. Crystalline Silica Dust is considered a hazardous material.

Greenlight Environmental Services provides silica monitoring services for any workplace where there is a risk of exposure to Respirable Crystalline Silica dust (RCS).

We use calibrated, light weight air monitors fitted to your workers with a cyclone filter head placed in the workers breathing zone. The cyclone head measures the portion of dust that is ‘respirable’ – which means that the dust will be deposited beyond the terminal bronchioles and into the gas exchange region of the lungs – it is this level of dust that needs to be accurately measured and compared to guideline levels in order to assess whether there is a risk to workers or not.

If your workplace potentially has silica dust, or Crystalline Silica is commonly used, it is vital that your workplace undergoes Silica Monitoring to ensure exposure levels to workers is less than the WHS Regulation Workplace Exposure Standards.

Why Customers Trust Greenlight Services

Manage Residential & Workplace Risks Fast

Audit your risks with fast turnaround time (3 days for most reports), experienced recommendations and our 100% satisfaction money back guarantee.